The sector

There are two parts to the New Zealand metals sector. Primary metals, which includes smelting and refining of iron ore and casting of the basic metals; and metal manufacturing, which includes iron and steel forging; structural steel; stainless steel; metal roofing sheet metals; steel pipes for geothermal, oil, gas, and water infrastructure; containers; and other metal products.

Supporting the sector in New Zealand is world-class research from the University of Auckland, University of Canterbury, Victoria University of Wellington, and Heavy Engineering Research Association (HERA).

It is commonly accepted that reducing construction wastage will improve both economic and environmental performance. This will involve establishing the necessary resourcing, information, data and tools to reduce both production-based and consumption-based emissions.

Change is happening – and it is vital we understand, inform, and inspire this transformation. The metals industry has come a long way over the last few decades, with fresh innovation, new processes, and cutting-edge technology ensuring we stay ahead of tomorrow.

New Zealand can lead the way with how valuable resources are created, constructed, recycled, and re-used.

The strength in metals

The innovation and long-ranging vision within the metals industry is delivering a smart, sustainable and ultimately strong future for New Zealand.

This collaborative and holistic approach between a wide range of partners ensures our valuable resources can be used to their true potential – be it in creation, construction or eventual recycling and regeneration.

This is how strength in metals can build strength in communities, and impel more sustainable outcomes. It is why metals will continue to help New Zealand meet tomorrow with confidence.

Strength in numbers.

Strength in purpose.

Strength in unity.

The beauty of metals

The beauty of steel and other metals is that they are incredibly adaptable and highly effective across a wide range of uses. It is the substance within the style that makes metals so valuable to our country.

Structural steel delivers resilient and enduring buildings, ensuring our communities are protected during seismic events and providing safe, healthy living and work environments. Iron and steel is used in everything from art to automobiles, and more and more different metals are now in use as the world’s technology evolves at an increased pace.

Many technologies important in the transition to a more circular economy (including wind turbines, solar panels, and batteries) require metal inputs. New Zealand is one of the world’s highest per capita users of stainless steel and it remains important to our economy and recycling journey.

Look closer and it’s easy to see the incredible value that metals add across every New Zealand industry, from ubiquitous strength to enduring functionality.

The game changer

New Zealand Steel’s 2023 announcement that it will partner with the New Zealand government to build a new Electric Arc Furnace (EAF) within the next three years is a game-changer. It is a crucial part of the country’s largest-ever emissions reduction project.

This significant investment will reduce New Zealand’s carbon footprint by at least 800,000 tonnes – the same as taking approximately 300,000 cars off the road permanently. It represents a reduction of over 45% in New Zealand Steel’s emissions, a total of 1% of New Zealand’s total annual emissions.

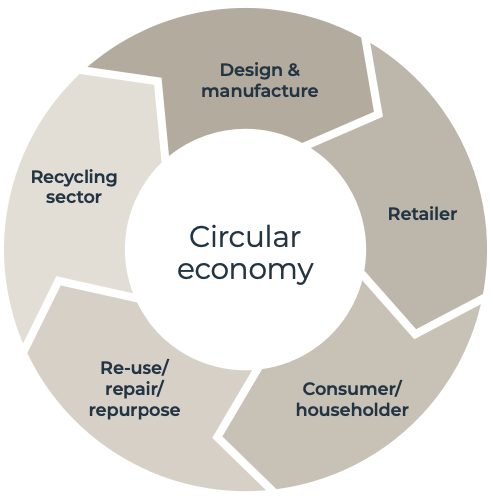

A circular economy

New Zealand now recognises the importance of long-term thinking in how we source, use and re-use resources. This is why Metals NZ supports policy aimed at aligning our country’s building and construction sector with circular economy principles.

Historically, our economy has predominantly used resources in a manner consistent with the linear ‘extract-make-use- dispose’ model. In contrast, a circular economy maximises the long-term sustainable use of resources and energy within production systems. In a circular economy, waste is designed out of the system to ensure the value of scarce resources is maximised through reusing, recycling and upcycling.

Research undertaken by HERA revealed approximately 85% of New Zealander’s building and construction steel waste is recycled or repurposed.

This recycling is less carbon-intensive than newly produced steel, with around 1000 kilograms of avoided emissions per tonne of steel recycled. So too can aluminium be recycled indefinitely, as reprocessing does not damage its structure. Increasing New Zealand’s recycling rates would further lower emissions.

While the intrinsic strength within metals is widely known, it is the ability to sustain a circular economy that makes these materials so much stronger. We must release the inherent value within metals again, and again, and again.